PVC plumbing, short for Polyvinyl Chloride plumbing, has become a staple in modern residential, commercial, and industrial plumbing systems. Its popularity stems from its lightweight structure, affordability, and strong resistance to corrosion and chemical wear. Commonly used in drain lines, irrigation systems, and cold water supply lines, PVC pipes offer a practical and efficient solution for long-term plumbing needs. Unlike traditional metal pipes, PVC plumbing does not rust or corrode, making it an ideal choice for environments with varying water qualities. It is also easy to install, requires minimal maintenance, and can withstand various pressures and flow rates. These characteristics contribute to its widespread use in both new construction and plumbing retrofits. However, homeowners, contractors, and property managers frequently ask, “How long does pvc plumbing last?” In this guide, we’ll explore the expected lifespan of PVC pipes, what factors influence it, and how you can maximize the durability of your plumbing system.

How long does pvc plumbing last?

PVC plumbing is known for its durability and longevity, making it a top choice for residential and commercial plumbing systems. Under ideal conditions, PVC pipes can last between 50 to 100 years, depending on the quality of materials, installation practices, and environmental factors. Most residential PVC plumbing systems typically have an average lifespan of 50 to 70 years.

The longevity of PVC plumbing depends largely on how the pipes are used and maintained. In cold water distribution and drainage systems, where pressure and temperature are moderate, PVC plumbing systems can perform reliably for decades. However, excessive water pressure, high temperatures, and direct exposure to UV radiation can reduce their service life.

Thanks to improvements in polymer technology and pipe manufacturing, many modern PVC pipes are more robust and resistant to environmental wear than earlier versions. When professionally installed and protected from damaging factors like sunlight and harsh chemicals, these pipes can easily exceed their expected lifespan.

Understanding how long PVC plumbing lasts helps property owners make informed decisions about maintenance, upgrades, and future replacements. With proper care, PVC plumbing offers a cost-effective, long-term solution for efficient water management in any building.

Factors That Affect the Lifespan of PVC Plumbing

Several key factors influence how long PVC plumbing lasts, and understanding them can help you better maintain your system and extend its longevity. Below are the most critical elements that affect the durability and performance of PVC pipes over time:

UV Exposure

One of the major threats to PVC plumbing longevity is prolonged exposure to ultraviolet (UV) radiation. When PVC pipes are left exposed to sunlight, especially in outdoor installations, UV rays gradually break down the chemical bonds in the plastic. This results in the material becoming brittle, discolored, and more prone to cracking or premature failure. Over time, even strong PVC will degrade if it’s not properly shielded. To protect your system and ensure your PVC plumbing lasts as long as possible, always insulate or bury exposed pipes or use UV-resistant coatings for outdoor applications.

Water Temperature

While PVC is suitable for cold water systems, it is not recommended for hot water applications. Elevated temperatures can soften the pipe material, causing it to lose its shape and mechanical strength. Repeated exposure to hot water accelerates wear, increasing the risk of leaks and pipe failure. For hot water lines, CPVC is a better choice as it is specifically designed to withstand higher temperatures. If you’re using standard PVC for water supply, make sure the water temperature stays within the manufacturer’s guidelines to help your PVC plumbing system last longer without compromising safety or efficiency.

Water Pressure

Excessive water pressure is another factor that can significantly impact how long PVC plumbing lasts. High pressure puts continuous stress on the pipe walls, joints, and fittings, increasing the likelihood of leaks, cracks, and even bursts. Over time, this wear and tear can weaken the entire plumbing network. PVC pipes are rated for specific pressure tolerances, so exceeding these levels shortens their lifespan. Installing a pressure regulator and routinely checking your system’s PSI helps maintain safe levels and ensures your PVC pipes perform reliably for decades without unnecessary strain or damage.

Soil Movement

For buried PVC plumbing systems, soil movement can be a silent but serious issue. Shifting ground caused by erosion, poor compaction, or seismic activity can place unexpected stress on pipes. Over time, this can lead to cracks, joint separation, or full system failure. The flexibility of PVC offers some resistance to movement, but it’s not immune to pressure from unstable soil. To extend the life of underground PVC plumbing, it’s essential to ensure proper trench depth, use gravel or sand bedding for stability, and backfill carefully. These practices protect your PVC plumbing from damage caused by soil displacement.

Chemical Exposure

Although PVC is known for its chemical resistance, repeated exposure to aggressive or corrosive substances, especially in industrial or agricultural settings, can degrade its material integrity. Strong acids, solvents, or oils may cause softening, cracking, or molecular breakdown over time. This weakens the pipe walls and increases the risk of failure. For environments with frequent chemical contact, using specially rated chemical-resistant PVC or alternative materials may be more appropriate. Always match the pipe material to the application to ensure your PVC plumbing system remains durable and resistant to environmental hazards.

Installation Quality

The lifespan of any PVC plumbing system heavily depends on the quality of installation. Incorrect pipe cutting, poor alignment, inadequate priming or gluing, and insufficient support can lead to serious long-term issues such as leaks, stress fractures, and water pressure imbalances. Proper installation practices—such as allowing curing time for solvent cement and using the right fittings—are essential to prevent future failures. Hiring qualified professionals ensures that your system is installed according to industry standards. A well-installed PVC system not only performs better but also achieves its full lifespan potential of 50 to 100 years.

How to Extend the Life of Your PVC Plumbing?

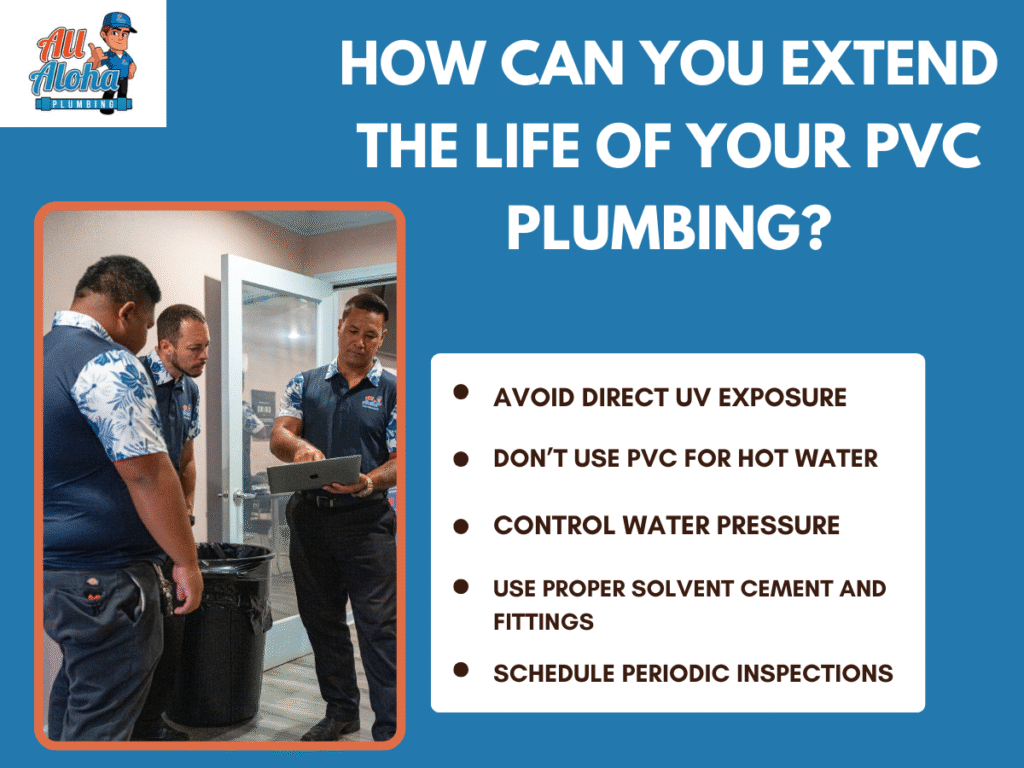

Extending the lifespan of your PVC plumbing system is entirely achievable with the right maintenance and precautions. Below are essential strategies to maximize durability and performance while reducing the risk of costly repairs or early replacements.

Avoid Direct UV Exposure

PVC pipes degrade when exposed to sunlight over time, especially in outdoor applications. Protecting them from UV rays helps preserve their structural integrity.

- Use UV-resistant pipe coverings or insulation when installing PVC outdoors.

- Consider painting exposed pipes with a latex-based UV-resistant paint.

- Bury outdoor PVC plumbing underground to shield it from sunlight.

- Install piping in shaded or enclosed areas whenever possible.

Don’t Use PVC for Hot Water

Standard PVC is not made to handle high-temperature water, which can weaken the material and cause failures.

- Use CPVC pipes (Chlorinated PVC), which are specifically designed for hot water systems.

- Always check manufacturer specifications before using PVC near water heaters or hot appliances.

- For combined systems, separate cold and hot water lines to prevent accidental temperature stress on PVC.

- Consider mixing materials for hybrid systems—PVC for cold water, CPVC or PEX for hot water.

Control Water Pressure

High water pressure can accelerate wear and tear on your plumbing, especially at joints and fittings.

- Install a pressure-reducing valve (PRV) to maintain safe, consistent water pressure.

- Monitor your home’s water pressure using a pressure gauge (ideal range is 40–60 psi).

- Address water hammer issues with arrestors or shock absorbers to prevent pipe stress.

- Inspect fittings and connectors periodically to catch any early signs of stress or leaks.

Use Proper Solvent Cement and Fittings

The integrity of a PVC plumbing system depends heavily on how well joints are sealed and connected.

- Use solvent cement that matches your pipe diameter and pressure rating.

- Ensure the pipe ends are cut clean, deburred, and dry before applying cement.

- Allow the proper cure time as specified on the product label to achieve strong bonds.

- Avoid overtightening or misaligning fittings during installation, which can weaken joints.

Schedule Periodic Inspections

Routine plumbing inspections help detect small issues before they turn into major plumbing failures.

- Hire a licensed plumber every few years to inspect your PVC pipes for signs of stress or wear.

- Look for signs of leakage, discoloration, or cracks around fittings and joints.

- Check outdoor plumbing areas after seasonal temperature changes for expansion or contraction.

- Keep records of all inspections and maintenance to track aging or vulnerable areas in your system.

Signs Your PVC Plumbing May Be Failing

PVC plumbing is tough, but not invincible. Be on the lookout for these signs that may indicate your PVC pipes are nearing the end of their life:

- Cracks, holes, or visible wear on the pipe surface

- Leaks at joints or fittings

- Water discoloration or unusual odors

- Reduced water pressure

- Frequent clogs or backups in the drainage system

Is Replacing PVC Plumbing Necessary?

While PVC plumbing is known for its durability and long service life, no plumbing system lasts forever. If your home or building’s plumbing system is 40 to 50 years old, it may be time to assess its current condition and determine if a full or partial replacement is necessary. Over time, even high-quality PVC pipes can experience wear and tear due to environmental exposure, water quality, soil movement, and repeated pressure fluctuations.

Older PVC systems are also more likely to have been installed using outdated materials or techniques that no longer meet current plumbing standards. Replacing aging PVC plumbing not only prevents unexpected failures but also offers long-term benefits in terms of performance, efficiency, and safety.

Benefits of Replacing PVC Plumbing:

- Enhanced Water Flow and Pressure: New piping systems ensure smooth and unrestricted water flow, eliminating issues such as low pressure caused by internal pipe damage or partial blockages.

- Reduced Risk of Leaks and Pipe Failures: Aging PVC pipes may become brittle, crack, or separate at the joints. A replacement eliminates the risk of costly leaks and water damage.

- Improved Water Quality: Older plumbing systems can sometimes affect water clarity or taste. Replacing outdated pipes helps maintain clean and safe water for daily use.

- Energy and Water Efficiency: Newer systems are designed for optimal flow, reducing strain on your plumbing and conserving water and energy over time.

- Compliance with Current Building Codes: Plumbing codes evolve over the years. Upgrading your PVC plumbing system ensures it meets current safety and efficiency standards, which is especially important during property sales or renovations.

- Peace of Mind: Perhaps most importantly, a new plumbing system provides confidence that your home’s water infrastructure is dependable and built to last for decades.

Comparing PVC with Other Plumbing Materials

| Plumbing Material | Lifespan | Advantages | Disadvantages |

| PVC | 50–100 years | Affordable, corrosion-resistant, easy to install | Not suitable for hot water |

| Copper | 50+ years | Handles hot/cold water, antimicrobial | Expensive, may corrode over time |

| PEX | 40–50 years | Flexible, easy to install | Vulnerable to UV rays and rodents |

| Galvanized Steel | 20–50 years | Durable in old systems | Rusts easily, heavy, hard to replace |

| CPVC | 50–75 years | Can handle hot water | More expensive than PVC, brittle |

Final Words

So, How long does pvc plumbing last? When installed correctly and maintained under suitable conditions, PVC plumbing systems can offer reliable performance for anywhere between 50 to 100 years. This impressive lifespan makes them a cost-effective and dependable option for homeowners and businesses alike. However, the actual longevity of your pipes depends on several key factors such as UV exposure, water pressure, temperature, soil conditions, and the quality of installation.

By understanding what affects the durability of your PVC pipes, performing routine inspections, and recognizing early signs of wear or damage, you can make informed decisions that protect your property and extend your plumbing system’s service life.

Whether you’re planning a new build, upgrading an outdated system, or simply assessing your current plumbing, knowing how long PVC plumbing lasts empowers you to invest wisely and avoid unexpected repairs in the future.