In plumbing systems, maintaining the purity of potable water is crucial for health and safety. One major concern is backflow, which occurs when water reverses direction, potentially allowing contaminants, chemicals, or bacteria to enter the clean water supply. This can result from back-siphonage or back-pressure, both of which pose serious risks to residential, commercial, and industrial plumbing networks. So, which plumbing device helps prevent a backflow? To prevent backflow, specialized plumbing devices, known as backflow preventers, are installed to ensure water flows in only one direction.

These devices play a vital role in protecting potable water systems from contamination and ensuring compliance with plumbing codes and regulations. Common backflow prevention devices include pressure vacuum breakers (PVBs), reduced pressure zone devices (RPZDs), and double-check valve assemblies (DCVAs), each suited to different hazard levels. Proper selection, installation, and regular maintenance of these devices are essential for preventing backflow and safeguarding water quality.

Choosing the right plumbing device to prevent backflow is critical for maintaining a safe and efficient plumbing system.

What is Backflow Prevention?

Backflow refers to the unwanted reversal of water flow, causing clean water to mix with contaminated water, which can lead to serious health risks. This contamination is especially dangerous in areas such as city water systems, food processing plants, and medical water supplies. To prevent such hazards, backflow prevention devices are installed in residential, industrial, and commercial properties. These devices ensure that water flows in the intended direction, stopping harmful substances from entering potable water systems. Many building codes mandate their use to protect public health by maintaining the purity of drinking water and preventing widespread contamination.

What are Air Gaps?

An air gap in plumbing is a simple yet effective backflow prevention method. It refers to the open, upright space between the water supply break and the flood level of a fixture. This gap ensures that contaminated water, such as wastewater, cannot flow back into the clean water system. Air gaps are commonly used to prevent reverse flow from household drains into potable water supplies. By maintaining this physical separation, wastewater is carried across the gap, preventing contamination. Many building codes require the installation of backflow prevention devices like air gaps in both residential and commercial properties to safeguard water quality.

Which plumbing device helps prevent a Backflow?

In plumbing systems, preventing backflow is crucial to maintaining a clean and safe water supply. A backflow preventer is the primary device used to stop contaminated water from reversing into potable water lines. It ensures a one-directional flow, preventing pollutants, chemicals, and bacteria from entering the drinking water system.

| Device Type | Mechanism | Typical Applications | Hazard Level Addressed |

| Atmospheric Vacuum Breaker (AVB) | Allows air into the system to prevent back-siphonage. | Toilets, urinals, hose bibs | Low |

| Pressure Vacuum Breaker (PVB) | Utilizes a spring-loaded check valve to prevent backflow under pressure. | Irrigation systems | Low to Medium |

| Double Check Valve Assembly (DCVA) | Contains two check valves in series for redundancy. | Fire sprinkler systems | Medium |

| Reduced Pressure Zone Device (RPZD) | Features two check valves with a pressure-monitored chamber between them. | Industrial processes, hospitals | High |

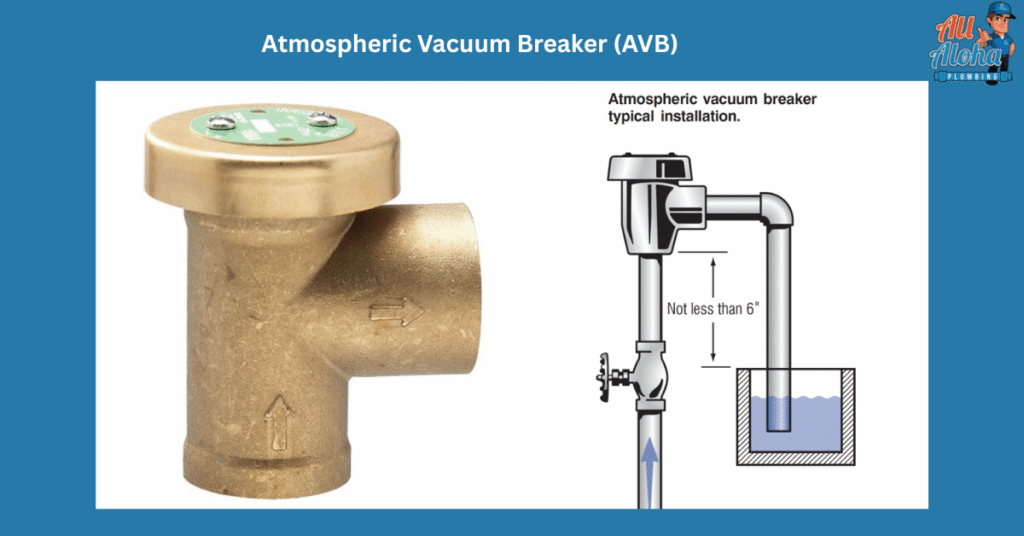

Atmospheric Vacuum Breaker (AVB)

An Atmospheric Vacuum Breaker (AVB) is a backflow prevention device designed to protect potable water systems from contamination due to back-siphonage. It is particularly used in low-risk applications such as irrigation systems, faucets, and other non-critical water connections. It works by allowing air into the system when there’s a sudden drop in pressure, preventing back-siphonage and stopping contaminated water from entering the clean water supply. AVBs are easy to install and maintain, making them ideal for residential use. However, they are not suitable for high-risk applications like food processing or medical systems. Many building codes require their installation to ensure water quality is protected.

- How It Works: AVBs have a hood-operated poppet valve that opens when system pressure drops, introducing air to break the siphon effect.

- Ideal Use Cases: Commonly installed in toilets, urinals, and outdoor hose bibs where back-siphonage is a risk.

- Limitations: AVBs cannot function under continuous pressure, meaning they should not be used where water is constantly flowing.

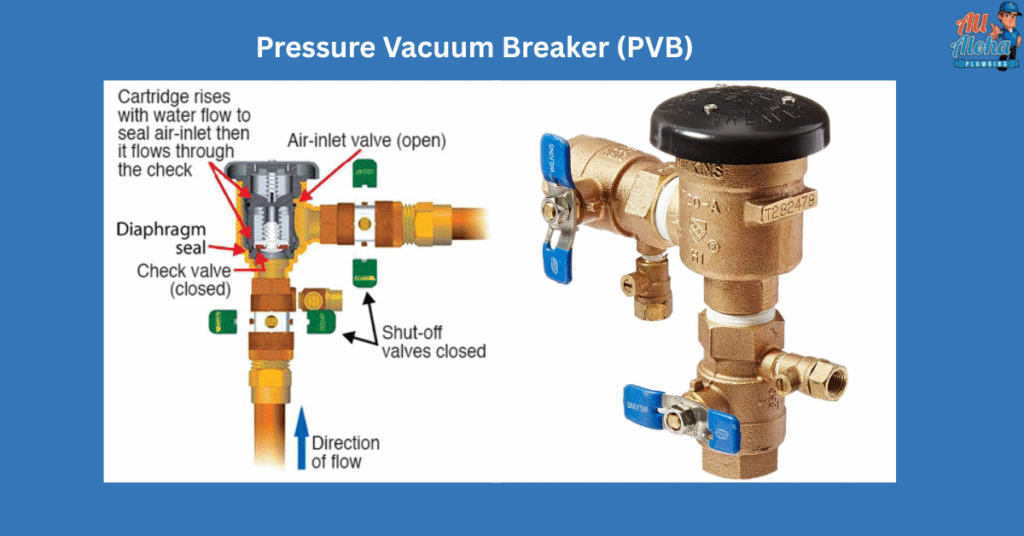

Pressure Vacuum Breaker (PVB)

A Pressure Vacuum Breaker (PVB) is a more advanced version of an AVB, designed to prevent contaminated water from flowing back into the clean water supply. Unlike the AVB, a PVB protects both back-siphonage and backpressure, making it suitable for a wider range of applications. It consists of a valve and an air inlet, which opens when the pressure drops, allowing air into the system and preventing backflow. PVBs are commonly used in irrigation systems, outdoor faucets, and other residential or commercial installations. They are reliable, easy to install, and provide an extra layer of protection against water contamination. However, they must be installed above the highest point of the system and require regular maintenance to ensure proper functioning.

- How It Works: PVBs use a spring-loaded check valve that remains closed under normal conditions. If back-siphonage occurs, the valve opens, allowing air to enter and break the vacuum.

- Ideal Use Cases: Best suited for irrigation systems, lawn sprinklers, and other outdoor plumbing setups where a pressure drop could pull contaminants into the system.

- Advantages: PVBs can operate under constant pressure, unlike AVBs, making them more versatile.

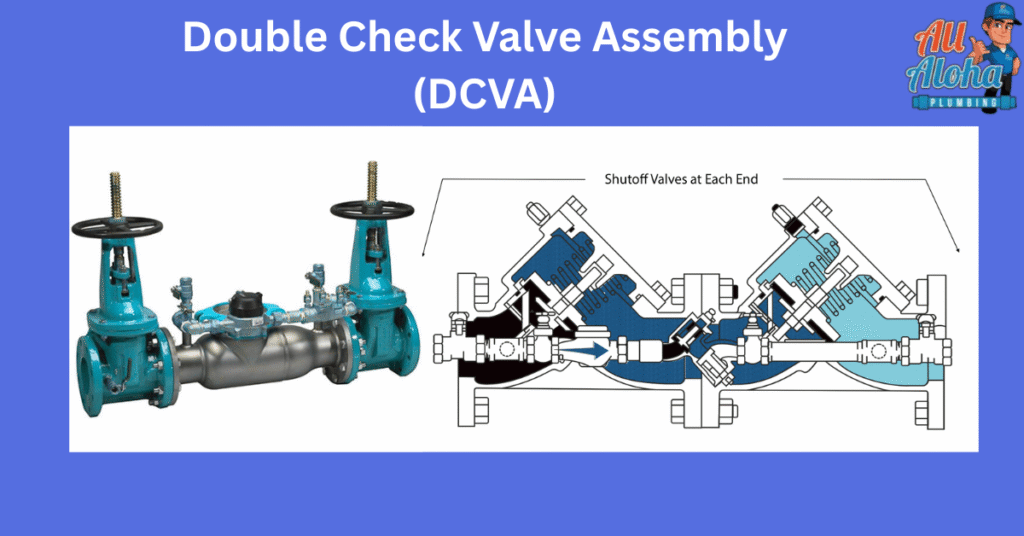

Double Check Valve Assembly (DCVA)

A Double Check Valve Assembly (DCVA) is a type of backflow preventer designed to protect drinking water supplies from potential contamination. It is commonly used in situations where the risk of contamination is low to medium, but there is still a need for reliable protection against backflow.

- How It Works: The Double Check Valve Assembly (DCVA) consists of two check valves in series, protecting against backflow. If water flows backward (due to back siphonage or back pressure), the first valve closes to block contamination. If the first valve fails, the second valve acts as backup. The assembly also includes a test cock and drain valve for maintenance and inspection, ensuring proper function.

- Ideal Use Cases: Used in fire sprinkler systems, food processing units, and non-toxic water sources where moderate backflow risks exist.

- Advantages: DCVAs are compact, cost-effective, and offer reliable performance in preventing back pressure and back siphonage.

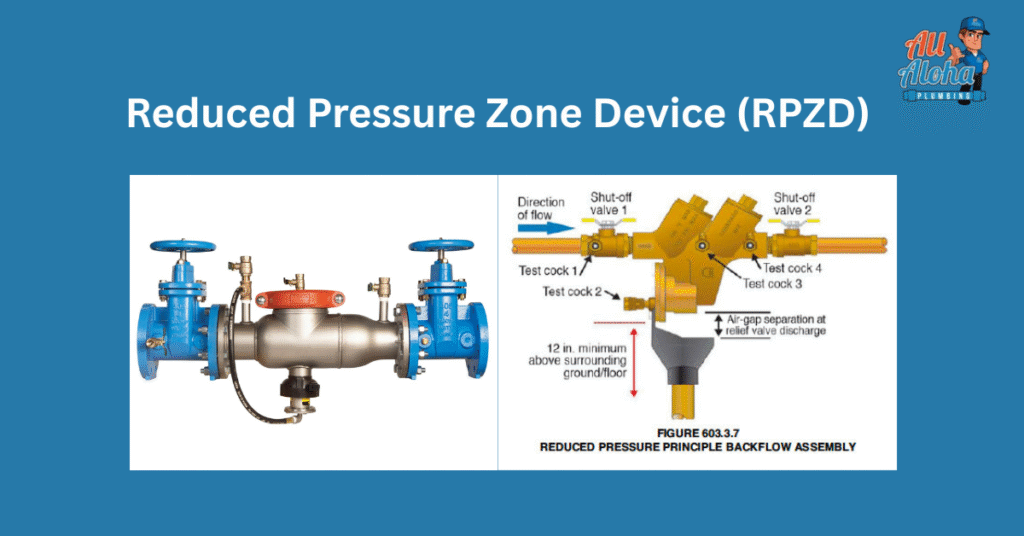

Reduced Pressure Zone Device (RPZD)

A Reduced Pressure Zone Device (RPZD) is the most advanced and highly reliable backflow prevention device, suitable for high-risk applications where contamination could pose serious health threats.

- How It Works: RPZDs consist of two check valves and a pressure-monitored chamber. If either check valve fails, the chamber will release excess water, preventing contaminated water from entering the potable supply.

- Ideal Use Cases: RPZDs are commonly used in hospitals, industrial plants, chemical processing facilities, and high-risk water systems where toxic substances could backflow.

- Advantages: This is the most effective type of backflow preventer, providing robust protection against contamination. However, RPZDs require regular maintenance and testing to ensure proper functionality.

What Causes Backflow & Why Is It Dangerous?

Backflow is a serious plumbing issue that occurs when the normal direction of water flow reverses, potentially contaminating the clean water supply. Understanding its causes and risks is essential for implementing proper prevention measures.

Back Pressure

Back pressure occurs when the downstream pressure in a plumbing system becomes higher than the supply pressure, forcing water to flow in the opposite direction. Several factors contribute to back pressure, including:

- Pump Malfunctions – If a pump in the plumbing system malfunctions or creates excess pressure, it can push contaminated water back into the clean water supply.

- Thermal Expansion – Water heaters or other heating systems can increase water pressure within the pipes, leading to back pressure and a potential backflow event.

- Elevated Piping Systems – In buildings with multiple floors, gravity can increase water pressure in lower levels, potentially forcing water to move in reverse if not properly regulated.

Back Siphonage

Back siphonage happens when there is a sudden drop in supply pressure, creating a vacuum effect that pulls water from private plumbing systems, irrigation systems, or other sources back into the main water supply. The most common causes include:

- Mainline Breaks – If a water main breaks or undergoes maintenance, it can create a significant drop in pressure, leading to back siphonage.

- Heavy Water Demand – When large volumes of water are drawn from the system, such as during fire hydrant use or major industrial operations, it can create negative pressure, causing backflow.

Why Is Backflow Dangerous?

Backflow poses serious health and safety risks because it can allow contaminants, including bacteria, chemicals, pesticides, and other hazardous substances, to enter the potable water supply. Without proper prevention measures, exposure to contaminated water can lead to waterborne illnesses, chemical poisoning, and other serious health hazards.

To ensure water safety, installing reliable backflow prevention devices and performing regular maintenance is essential. Compliance with local plumbing regulations and scheduled inspections will help safeguard public health and maintain the integrity of drinking water systems. By implementing effective backflow prevention strategies, property owners, businesses, and municipalities can minimize risks and ensure a safe, clean water supply.

How to Choose the Right Backflow Preventer?

Selecting the right backflow preventer is crucial for ensuring the safety and efficiency of your plumbing system. Several factors influence this decision, including the level of hazard, system pressure, maintenance requirements, and compliance with local regulations.

Hazard Level Assessment

The hazard level of your plumbing system plays a significant role in determining the appropriate backflow prevention device.

- Low-Risk Applications – If your system is only at risk of minor contamination (such as non-toxic water sources mixing with potable water), devices like Atmospheric Vacuum Breakers (AVBs) or Pressure Vacuum Breakers (PVBs) are often sufficient. These are commonly used in irrigation systems, residential outdoor faucets, and low-risk commercial applications.

- High-Risk Applications – If your system is dealing with hazardous chemicals, industrial fluids, or other toxic substances, a more robust backflow preventer is required. In such cases, a Reduced Pressure Zone Device (RPZD) is the best option. This is commonly used in medical facilities, chemical plants, and industrial applications where contamination could be dangerous to public health.

SEO Tip: Including terms like “best backflow preventer for home use,” “industrial backflow preventers,” and “low vs. high hazard backflow devices” can help improve search rankings.

System Pressure Considerations

Each backflow prevention device is designed to operate within a specific pressure range. Choosing a device that can handle your system’s water pressure is essential to avoid malfunctions.

- Continuous Pressure Systems – Systems that maintain constant pressure, such as fire sprinkler systems or municipal water supplies, require backflow preventers that can operate under these conditions. Double Check Valve Assemblies (DCVA) and RPZDs are suitable options.

- Intermittent Pressure Systems – Systems that operate periodically, such as garden irrigation systems or residential plumbing setups, can use PVBs or AVBs, which function effectively under fluctuating pressure conditions.

SEO Tip: Using keywords like “backflow preventer for high-pressure systems” and “best backflow preventer for irrigation” can enhance visibility.

Maintenance and Testing Requirements

Backflow prevention devices require regular testing and maintenance to ensure optimal performance. Some devices have more stringent maintenance requirements than others.

- Annual Testing – Certain backflow preventers, such as RPZDs and DCVAs, must undergo annual testing and certification by a licensed professional. This ensures they remain in compliance with health and safety regulations.

- Minimal Maintenance Options – If you’re looking for a low-maintenance solution, PVBs and AVBs require less frequent inspections but may still need periodic replacement of worn-out components.

- Replacement & Repairs – Consider the availability of replacement parts and whether the device can be easily repaired in case of failure.

SEO Tip: Targeting queries like “how often to test backflow preventers” and “low-maintenance backflow prevention devices” can drive organic traffic.

Compliance with Local Regulations

Which plumbing device helps prevent a Backflow? Backflow prevention laws vary by location, and compliance is mandatory in most regions.

- Many local plumbing codes specify the types of backflow preventers required for different applications.

- Certain industries, such as healthcare, food processing, and municipal water systems, have strict backflow prevention standards to ensure public safety.

- Failing to install the right device can result in fines, legal liabilities, and water supply contamination risks.

Before purchasing a backflow preventer, consult your local plumbing authority or a licensed plumber to ensure you meet legal requirements.

SEO Tip: Phrases like “backflow prevention laws by state,” “do I need a backflow preventer?” and “plumbing code for backflow prevention” can attract users searching for regulatory guidance.

Final Words

So, which plumbing device helps prevent a backflow? Preventing backflow is a critical aspect of maintaining a safe and clean water supply, ensuring that contaminants do not enter the potable water system. Backflow prevention devices play a vital role in safeguarding water quality by allowing water to flow in only one direction.

Understanding the different types of backflow preventers such as Atmospheric Vacuum Breakers (AVB), Pressure Vacuum Breakers (PVB), Double Check Valve Assemblies (DCVA), and Reduced Pressure Zone Devices (RPZD) enables property owners, facility managers, and plumbers to choose the most effective solution for their specific plumbing system.

Beyond installation, routine testing, maintenance, and compliance with local plumbing regulations are essential to ensure these devices function optimally. Neglecting backflow prevention measures can lead to severe health risks, legal penalties, and costly repairs due to water contamination

Frequently Asked Questions

Q1: Which plumbing device prevents backflow?

Ans: Backflow preventers like Double Check Valve Assemblies (DCVAs), Pressure Vacuum Breakers (PVB), and Check Valves are used to prevent backflow. They block contaminated water from flowing back into the clean water supply.

Q2: How do you prevent backflow in plumbing?

Ans: Backflow is prevented by installing devices such as DCVAs, RPZ valves, and PVBs in key areas of the plumbing system. These devices stop water from reversing direction and contaminating the supply. Regular testing and maintenance are also necessary.

Q3: What is the purpose of a pressure vacuum breaker?

Ans: A Pressure Vacuum Breaker (PVB) prevents back siphonage by allowing air into the system when negative pressure is detected. It stops contaminated water from being drawn back into the water supply, typically used in irrigation systems.

Q4: Does every house need a backflow preventer?

Ans: Not every house needs one, but backflow preventers are required by local codes in certain situations, like for irrigation systems, pools, or homes near potential contamination sources. It depends on local regulations and the risk of contamination.

Q5: How can we prevent air backflow?

Ans: Vacuum breakers or air gaps prevent air backflow by introducing air into the system to stop reverse water flow. These devices maintain pressure and prevent siphoning of contaminated water back into the clean supply.